TRANSMISSION TRAINING YARD UNIT

What’s New?

Transmission Unit Released in 2019!

- Now you can train your team on voltages up to 138kV!

- Voltages include:

- 34kV for Hot Sticking

- 69kV

- 138kV

- PROCESSOR SCAN TIMES: Average Scan Time: 1-2 ms/program cycle

- SAFETY RELAY INFO: SIL 3 Release Time: t

- SAFETY RATINGS:

- Fail Safe I/O: SIL Level 3 (per IEC 61508)

- Safety Relay (Master) SIL Level 3 (per IEC 62061)

- SIL Level 3 as above

- INTERNATIONAL ELECTRO-TECHNICAL COMMISSION (IEC) STANDARDS INFO:

- IEC 61508 – Electrical Safety of Electrical/Electronic/Programmable safety related systems

- IEC 62061 – Safety for Machinery

- MISC SAFETY INFO: 00001A (10µA) Increments

- Main Disconnect Handle allows (3) simultaneous Lock-Out-Tag-Out systems;

- System reset and initialization requires a supervisory key;

- High-Voltage Energize pushbutton is protected under a pad-lockable safety cover;

- System Safe/Off pushbutton utilizes redundant normally closed contacts, one of which is Normally Closed Self-Monitoring;

- E-Stop Pushbuttons utilize SIL3 redundant sets of normally closed contacts, one of which is Normally Closed Self-Monitoring;

- Master Safety relay can only be reset by inserting the supervisory key and indexing the RESET selector switch to the Safety position – the controller cannot reset the safety relay via program. (The master safety relay must be reset once power is applied to the panel before operation can commence.);

- Panel doors have coded magnetic door switch with SIL3 redundant N.C. contacts in line with the master safety relay;

- High-Voltage is physically isolated inside control panel from low voltage.

- LISTINGS UL 508A Industrial Control Panel

FAQs

Q: Will Timpson install the system in our training yard?

A: Unfortunately no, Timpson does not possess the capabilities to install our systems throughout the country and/or globally. We can however, work to answer any questions that your installation contactor may have. We also have Bulletin 2300 – Training Yard Installation Manual available for download on our website.

Q: Can Timpson provide us with info on the concrete pad/slab requirements?

A: Timpson cannot provide these requirements as local codes and soil constraints differ from location to location.

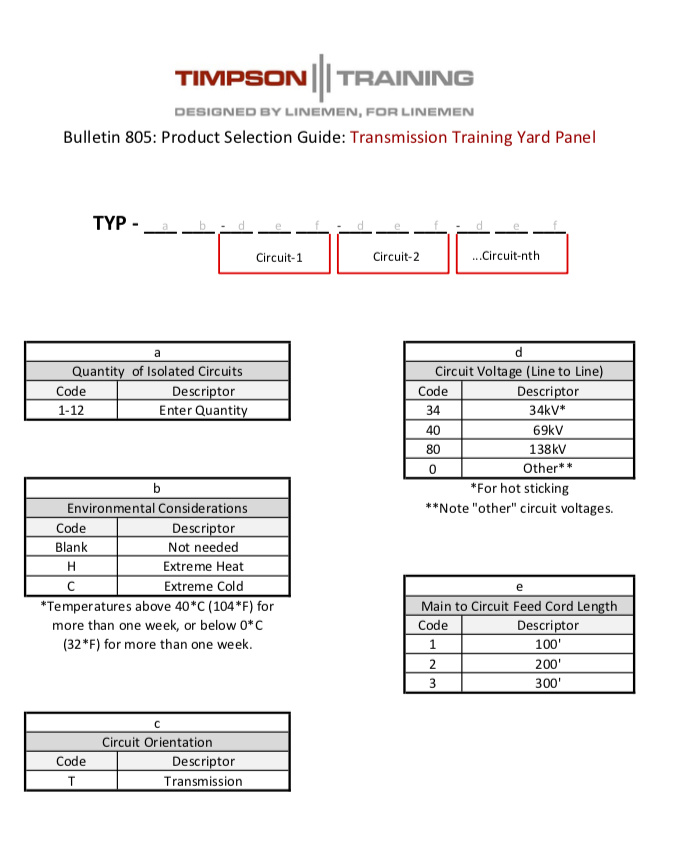

Q: What is the environmental rating of the panel?

A: All Training Yard systems are constructed to meet Nema 4 (IP66) requirements. However, some environments will require additional consideration from the Timpson engineers. For instance, extreme heat with temperatures over 104*F for more than a week at a time, and extreme cold with risk of ice build-up, must be brought to our attention prior to ordering.

Q: What is the system capable of energizing in my yard?

A: The system is capable of energizing the lines, and secondary transformers – without load. Basically, only the excitation current of transformers will be recognized at start-up and allowed to become energized. The system is only capable of outputting 30mA of total line current, as a secondary means of safety.

Q: What size concrete pad do I need to set the unit on?

A: Please refer to the “Mounting Pad” section of the Installation Manual (Bulletin 2300)

Q: Where do I bring the conduits up through the concrete pad?

A: Please refer to the “Mounting Pad” section of the Installation Manual (Bulletin 2300)